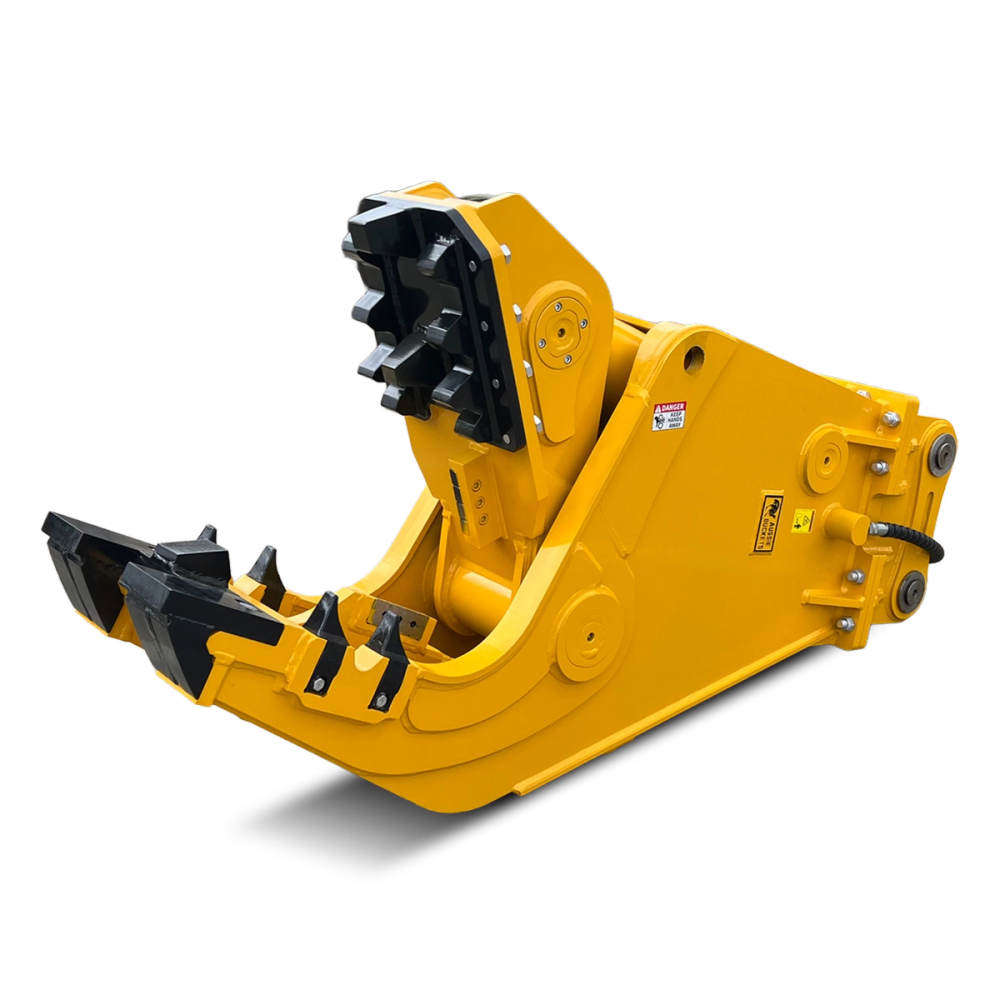

Rotating Pulveriser

Available for 15T - 50T

Starting from (ex. GST) $20,073 AUD $28,675

Or with AB 0% Finance from $145/week (ex. GST)

Crafted from HARDOX 500, the body and cutting areas provide exceptional wear resistance and durability, ensuring prolonged service life even in the most demanding demolition environments.

Designed with a reversed cylinder and optimised manifold blocks, the Fixed Pulveriser protects hydraulic components and simplifies hose routing, reducing maintenance needs and boosting operational reliability.

Integrated balance and speed valves on all models prevent hydraulic droop and optimise cycle times, delivering faster, more efficient operation and maximising project throughput.

The advanced single-tooth jaw design maximises crushing force for efficient breakdown of concrete and other materials, while integrated cutting blades effortlessly handle reinforced materials like rebar, enhancing versatility and performance.

Equipped with replaceable top jaw plates, bottom jaw tip plates, and teeth, alongside top-mounted access panels, the pulveriser ensures quick and easy servicing, minimising downtime and extending operational life.

A redesigned, widened material exit channel ensures efficient discharge of crushed material, preventing blockages and allowing only uncrushed material to remain, significantly boosting productivity.

Select a feature to highlight on image