GGlloobbaall--SSccaallee MMaannuuffaaccttuurriinngg

EExxcceelllleennccee

See Our Process

EExxcceelllleennccee

Our Global Presence

We have achieved manufacturing excellence across multiple continents.

Process

15 Steps to Perfection

From initial design to final delivery, every Aussie Buckets attachment goes through our rigorous 15-step manufacturing process.

Design & Engineering

The design and engineering phase involves finalizing detailed plans and CAD designs for excavator attachments based on customer orders, either from the standard range or custom requests. This ensures the attachment meets performance, safety, and compatibility requirements, including specific pin sizes and customer specifications, to prepare for manufacturing.

- Create and finalize CAD models based on customer-approved specifications, including pin size declarations.

- Select high-strength materials tailored for standard or custom attachment designs.

- Verify that provided data matches on-file information to ensure correct connection compatibility for the customer.

Raw Materials Selection

Based on the customer's order, machine class, site conditions, and customization requests, Aussie Bucket selects the most suitable steel grades to maximize value and performance. A vast range of steel grades is stocked, from mild steel to Bisalloy, Hardox, Hardox Tuf, and Hardox Strenx, ensuring optimal durability and functionality.

- Evaluate customer order, machine class, and site conditions to determine ideal steel grades.

- Select from a wide stock of steel, including mild options, BIS 400 - 500, Hardox 400 - 600, Hardox 500 Tuf, and Strenx 700.

- Ensure chosen materials meet customization requests for maximum value and performance.

Cutting Steel & Prep

This stage involves programming laser decks to transform CAD designs into precisely cut steel components. The process focuses on efficiently cutting all required parts, followed by deburring, cleaning, and labelling to ensure quality and streamlined manufacturing part management.

- Program CNC laser or plasma cutters to efficiently cut steel components from CAD designs.

- Deburr and clean-cut edges to ensure smooth surfaces for welding.

- Label and organize components for efficient tracking and assembly in manufacturing.

Bevelling

The bevelling phase prepares steel edges by creating precise angled cuts for cutting edges and other components in excavator attachments, improving penetration, reducing wear, and enhancing overall working operation. This process is conducted using advanced 5-axis bevelling robots, or large machinery, which allow for complex angles and contours on plates or sections, ensuring high accuracy and efficiency in steel fabrication.

- Use 5-axis bevelling robots with plasma or oxy-fuel tools to create specific angles on steel for cutting edges.

- Prepare beveled edges to optimize weld penetration or functional performance in attachments like buckets.

- Inspect beveled components for precision and quality to ensure smooth integration in assembly.

Steel Bending

The steel bending phase involves bending, folding, or primarily rolling steel to create curved sections for attachments such as buckets and grabs, ensuring precise shapes that meet design specifications for functionality and strength.

- Use rolling machines to form curved steel sections for buckets and grabs.

- Apply bending or folding techniques to achieve precise shapes per design requirements.

- Inspect bent components to ensure accuracy and alignment for assembly.

Assembly (Bracket / Splicing)

The assembly phase involves mechanically arranging and temporarily joining cut steel components to form the basic structure of the excavator attachment, excluding hydraulics or electronics. Components are placed in a jig, tacked together, and checked for squareness and correct distances to ensure precise alignment before primary welding.

- Position and secure steel components in a jig based on design specifications.

- Perform tack welding to temporarily join parts for structural stability.

- Check distances and ensure the unit is square to confirm alignment accuracy.

Welding

The welding phase permanently joins the tacked steel components of the excavator attachment using primarily robot welding machines, with final pieces welded by hand, to create a robust and durable structure capable of withstanding heavy excavator use. Robot welding ensures higher quality welds and larger single beads for enhanced strength.

- Utilize robot welding machines to create high-quality, large-bead welds for most components.

- Weld final pieces by hand to complete the attachment structure.

- Ensure welds pass ultrasonic testing and are consistent meeting industry standards.

Inspection PT / UT

The inspection phase uses Penetrant Testing (PT) and Ultrasonic Testing (UT) to ensure the quality of welds and components in the excavator attachment, identifying surface and internal imperfections without damaging the structure. PT applies a penetrant to reveal surface cracks, while UT uses ultrasonic waves to detect internal flaws, ensuring the attachment meets strict quality and safety standards.

- Apply penetrant and developer in PT to detect surface cracks and imperfections in welds.

- Use UT probes to scan for internal defects, ensuring structural integrity of critical components.

- Document inspection results to confirm welds and components meet quality standards.

Boring

The boring phase involves machining precise holes in the welded excavator attachment to accommodate pins, pivot joints, and hydraulic components, correcting micro-movements caused by welding. Line boring ensures a 100% perfect fit for smooth, long-term operation, reducing stress on pins and enhancing attachment durability.

- Use CNC line boring to create precise holes for pins, pivot joints, and hydraulics.

- Correct micro-movements from welding to ensure accurate tolerances and fit.

- Clean and deburr holes to minimize stress and ensure smooth operation.

Blasting

The blasting phase cleans the excavator attachment's surface using articulating recycled sand blasting machines, an environmentally friendly method, to remove contaminants, weld spatter, grease, and oil. This ensures a perfectly clean surface, free of imperfections, for optimal painting preparation and enhanced durability.

- Use articulating recycled sand blasting machines to clean steel surfaces in an eco-friendly manner.

- Remove weld spatter, grease, oil, and imperfections to ensure a smooth finish.

- Inspect surfaces to confirm they are clean and ready for painting.

Painting

The painting phase applies protective coatings to the excavator attachment, using filler putty to address steel imperfections from manufacturing, ensuring corrosion resistance and a beautiful, professional finish that meets customer-specified branding and expectations.

- Apply filler putty to smooth out steel imperfections for a flawless surface.

- Spray primer and high-durability paint in customer-specified colors or branding.

- Ensure even coating and proper curing for maximum durability and aesthetics.

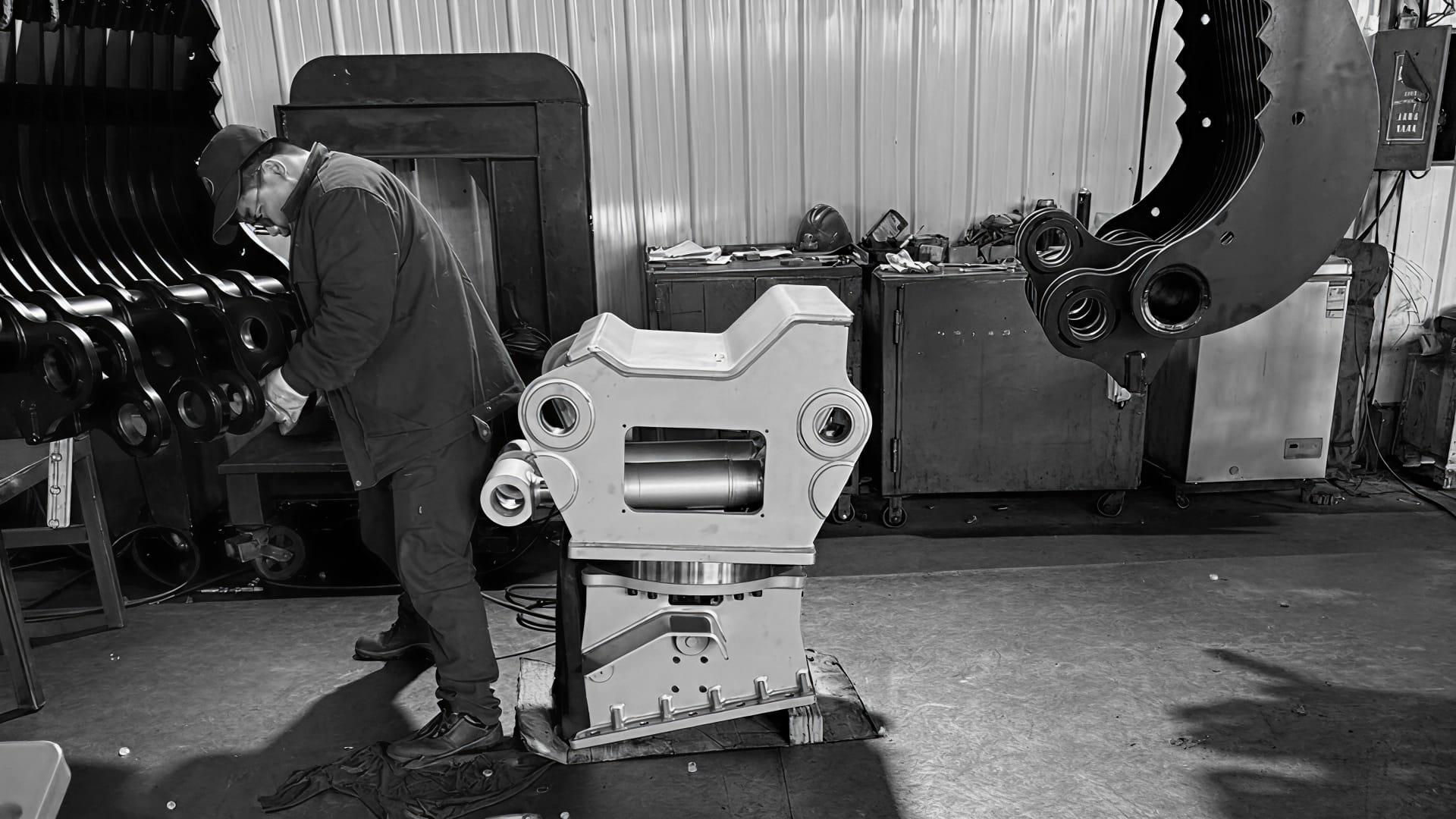

Final Assembly

The final assembly phase integrates all components, including serial plates, hydraulic cylinders, computers, electronics, pins, bushings, and attachment-specific parts, to complete the excavator attachment. Full-cycle testing ensures all components function smoothly and the unit is in operating readiness.

- Install serial plates, hydraulics, computers, electronics, pins, and bushings for complete functionality.

- Attach wear parts and other components specific to the attachment type.

- Perform full-cycle testing to verify smooth operation and operating readiness.

Quality Control

The quality control phase rigorously inspects and tests every component and manufacturing step to ensure the excavator attachment meets strict performance, safety, and durability standards. This includes verifying welds, paint, hydraulic seals, electrical systems, pin sizes, final dimensions, weight, and more.

- Conduct final inspections of welds, paint, hydraulic seals, and electrical systems for quality and consistency.

- Verify pin sizes, final dimensions, and weight against design specifications.

- Perform load, stress, and functional tests to confirm structural integrity and performance.

Packaging and Shipment

The packaging and shipment phase involves preparing the finished excavator attachment for safe transport by placing it on purpose-built wooden or steel pallets, securely strapping and wrapping it for maximum protection. The attachment is labeled alongside the customer's order and shipped to a distribution warehouse for delivery.

- Place attachments on purpose-built wooden or steel pallets and securely strap and wrap for protection.

- Label packages with handling instructions and customer order details.

- Coordinate shipment to the distribution warehouse for timely delivery.

Australian QC

The Australian Quality Control phase occurs at the distribution warehouse, where staff group customer orders from multiple manufacturing locations, verify product specifications and pin size declarations, and confirm or add components and accessories, including any final customer requests. Attachments undergo final QC checks to ensure readiness for dispatch to the Australian market.

- Group customer orders and verify product specifications and pin size declarations match the attachment.

- Confirm or add components and accessories, incorporating any final customer requests.

- Conduct final QC inspections to ensure the attachment is ready for dispatch.

Manufacturing Streams

Specialized production capabilities for diverse industry needs

Custom Fabrication

Tailored solutions for specific machines and applications. Bespoke attachments designed to your exact specifications.

- Bespoke design engineering

- Precision manufacturing

- Application-specific solutions

- Direct client collaboration

Mining Buckets & Attachments

Specialized engineering for demanding mining operations. Built to withstand extreme conditions.

- Heavy-duty construction

- Extreme wear resistance

- High-capacity designs

- Mining-grade materials